Good filtration cuts frustration

Experienced engineers report that 10% – 15% of all application issues can be traced back to poor filtration. But for a sprayer’s filters to work effectively, they must have a suitable mesh size and be regularly inspected and cleaned.

Before starting work ensure you are wearing full PPE, including a face shield. Use the isolating valves on the sprayer to prevent the loss of tank contents, while jugs and drip trays should be used to catch any spillage.

Poor nozzle filtration can cause uneven application by ‘fooling’ rate controllers into under- or over-applying to compensate for blocked nozzles and other problems. You won’t know because the electronics will still indicate everything is OK.

A blocked filter will cause flow-based controllers to increase pressure, which will increase drift. With a pressure-based controller the output will decrease because the pressure doesn’t change and flowrate reduces. This often results in left-over liquid in the tank.

Suction filters

Fitted immediately before the pump, suction filters protect its components from impurities in tank mixes. They are the largest of the inline filters as they will screen all liquid drawn into the pump, up to maximum pump flowrate.

Typically, recommended suction filters are relatively coarse (30 or 50 mesh size), with the specific size required indicated on the filter bowl. Don’t fit too finer suction filter, because this can cause cavitation and damage the pump.

Pressure filters

Installed after the pump, pressure filters remove particles and undispersed products from the pressurised spray mix and prevent blockages and damage to control units, valves and nozzles.

The key is to select a pressure filter that will be fine enough to remove any particles, but not too fine so that the filter is easily blocked by undispersed products, for example when using wettable powder formulations.

Typically, 04 to 08 nozzles will need 50 mesh filters, while smaller ones – from 01 to 03 – may need finer filters (80/100 mesh) to avoid blockages.

Check the chart

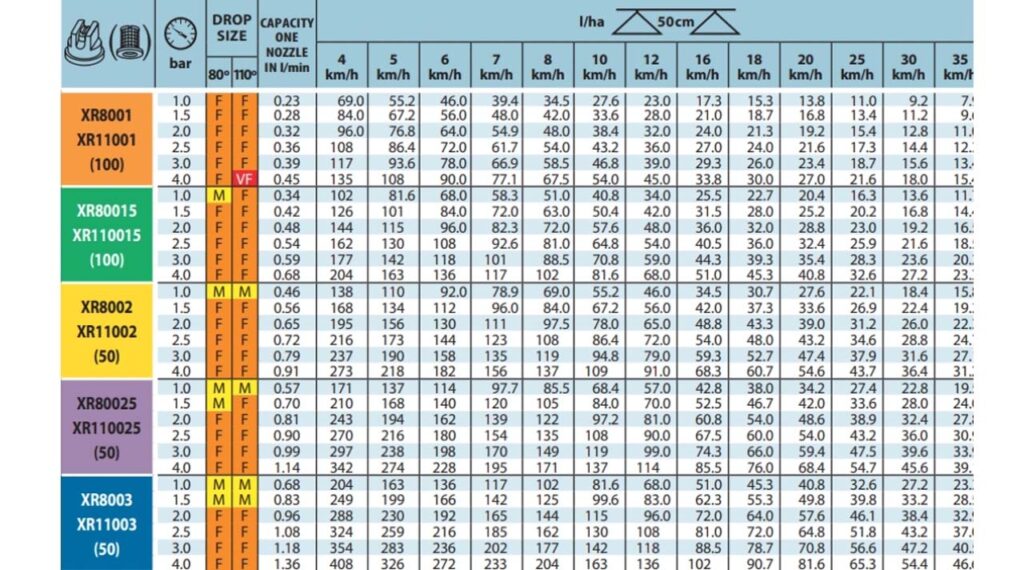

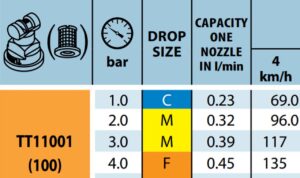

Most Nozzle manufacturers now provide recommended pressure filter sizes on their nozzle flow rate charts. For example, for an Teejet XR 11003 it is a 50 mesh, which is shown in its nozzle chart (below).

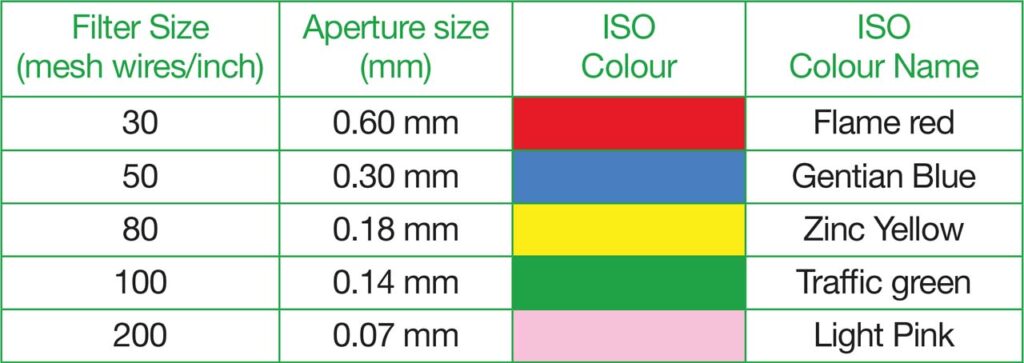

It is important to note that the filter colour does NOT necessarily correspond to the same colour as the nozzle. Filter mesh sizes/colours are classified in the ISO Standard ISO 19732 (see table). While this was introduced in 2011, it’s only recently become more widely adopted.

Prior to this, filters were colour coded according to the manufacturers’ own preferences – they did not follow any standard. So, on older machines, check the mesh size not the colour. Older filters can be readily replaced with new standardised filters, but bowls may need replacing.

Many nozzle manufacturers now provide recommended pressure filter sizes on nozzle flow rate charts to help operators. However, be careful not to select excessively fine filters, which may cause the filter to become clogged with undispersed product, particularly when using wettable powder formulations.

Click the image to download a typical nozzle chart, showing filter sizes.

Additional pressure filters, such as inline pressure filters on boom sections or nozzle filters, may also be fitted. Again, check the mesh sizes match the nozzles.

Filter cleaning

Check the filter mesh is not blocked and the housing is clean. Check for tears – where the mesh has come away from the screen, allowing unfiltered liquid to pass through. This can often be the reason why nozzles are blocking up for no apparent reason.

Filters are best cleaned by soaking them in water and using a soft brush to remove any residues.

This article is an extract from the eight-point Essential Maintenance course. Which you can purchase on the website.