Tips to stay compliant in store

Recently Health and Safety Executive (HSE) farm inspections have been focusing on pesticide storage. About 2,500 inspections have been carried out in the past five years, and while the majority result in no action, they have revealed a number of common ‘Non-Compliance Issues’.

The frequently found problems on farms include:

- Inadequate bunding: The most common issue is cracked, damaged or non-existent bunding (secondary containment) in the pesticide store, which fails to prevent leaks

- Unauthorised products: Storage of ‘withdrawn’ products that are no longer approved for use

- Poor storage practices: Pesticides not kept in original, labelled containers or stored in unsafe, insecure or unventilated areas

- Spill kit deficiencies: Inadequate spill kits (e.g. lacking necessary absorbent materials, brushes, shovels or proper PPE)

- Safety equipment failures: Tight-fitting respiratory protective equipment (RPE) being provided to operators who are not clean-shaven or have not had a face-fit test

- Lack of registration: Failing to register the business as a professional user of PPPs.

These all result from a failure to comply with the Code of Practice for using Plant Protection Products (CoP).

Comply with the Code

While the Code of Practice states the rules and regulations users need to follow, it also provides useful guidance on storage, best practice store management and record keeping.

The HSE provides a useful, detailed Information Sheet – “Guidance on Storing pesticides for farmers and other professional users” which you can download HERE:

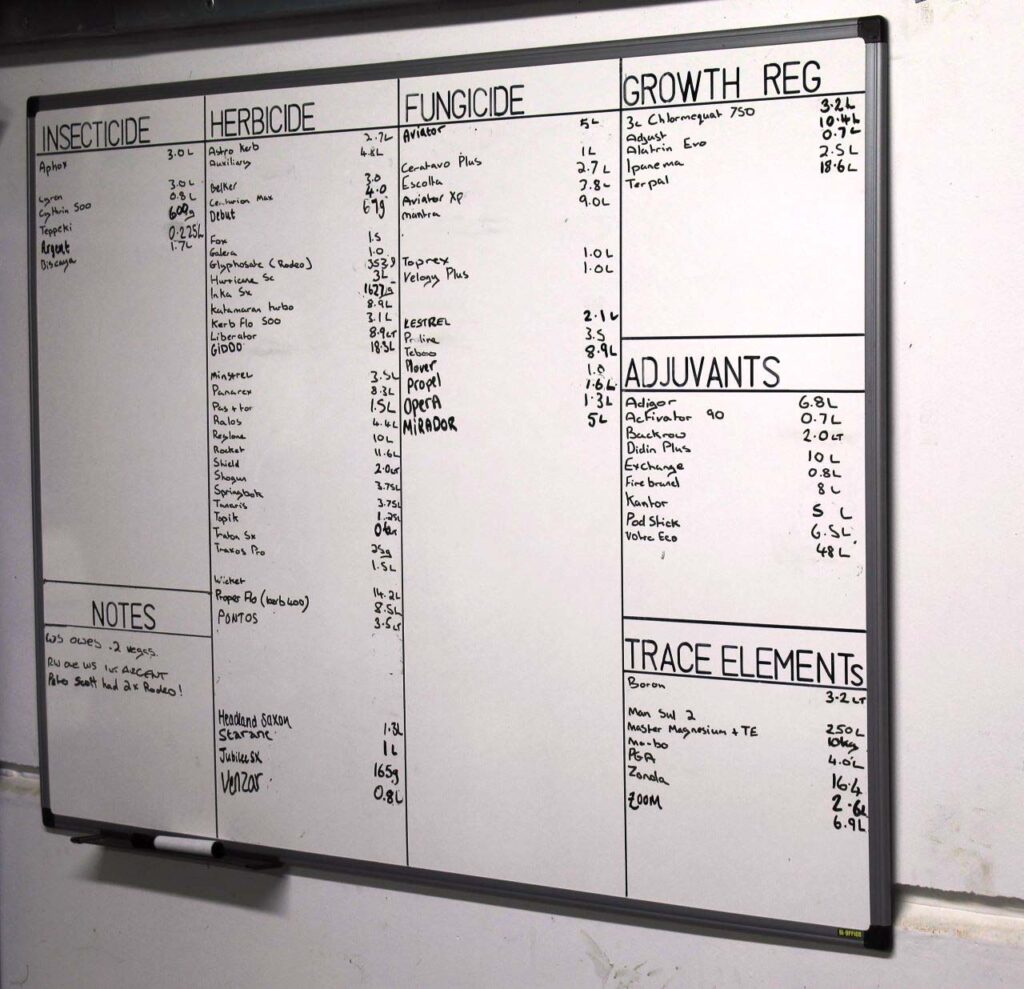

This good example of a tidy, clean and compliant store has a fully bunded and sealed floor, products stored in a separate lockable area, first aid and spill kit close to hand and even a hose gantry to prevent trips.

VI storage advice sheet

Further useful advice can be found on the Voluntary Initiative’s Pesticide Storage advice sheet. It provides advice and a helpful check list to conduct a self-assessment to check compliance.

You can download a copy HERE:

Best practice in store

The Code of Practice says pesticide stores must be resistant to fire, capable of retaining leakage and spills as well as be dry, frost free, adequately ventilated and secure against unauthorised access.

Owners and operators must also ensure a store and its contents are maintained and managed to continue to meet the standards.

Storage requirements

Store size:

Stores must safely hold the peak pesticide requirement, any part used containers and be able cope with stock build up, perhaps due to poor weather.

Bunding:

Stores must be able to retain leakage or spillage to a volume of 110% of the total quantity of products likely to be stored (185% if you are in an Environmentally Sensitive Area (ESA).

Location:

Stores must be located away from fire risk areas and be at least 4m away from combustible materials, houses and sources of ignition (e.g. workshops).

Site stores away from drains, water courses, wells, boreholes and areas liable to flood.

Construction materials:

The store, including doors but not the roof, should be made of a material which will resist fire for 30 minutes or longer. It should be fitted with fire doors or wooden doors must be lined with metal. Bunds need to be constructed of a non-fragile material that can resist penetration by liquid. They must comprise, or extend around, the whole store periphery.

Security:

All stores must be secured against unauthorised access when not in use. Windows must be secured.

Signage:

The exterior of the store, or building in which it is located, must display the general danger warning sign and ‘No Smoking’ or ‘Naked flames forbidden’ sign.

Lighting:

Provide natural and/or artificial lighting to enable the reading of product labels.

Heating:

Provide suitable heating to protect stores from frost. Heaters with exposed elements are not suitable.

Ventilation:

Controllable ventilation is available to control humidity and vapour levels in the store.

Product segregation:

Provision must be available to store powders above liquids, while flammable products must be stored away from exits.

Store records:

Accurate stock records and emergency contact details must be available. Stock records must be duplicated, with one kept away from the store.

How to register PPPs

Since June 2022 all users of plant protection products (PPPs) must have registered their storage and use on an HSE database. Results from recent inspections, however, show the failure to register is one of the most common non-compliances.

Who needs to register?

- If you use professional PPPs as part of your work

- Have professional PPPs and any adjuvants applied by a third party as part of your work in agricultural, horticultural, amenity or forestry.

What do you need to register?

- Your name

- Your business address

- Information about the PPPs you use and/or store in a typical year

How do you register?

Full details on how to register are available HERE:

Earn two NRoSO/BASIS points by completing the Safe & Legal in Stores Course here on the website.