Although Agritechnica always throws up a few surprises, few were expecting to see a mid-range Mazzotti sprayer in John Deere colours. We take a close look at the new machine, which recently made its UK debut at a demo arranged by the Hunt Forest Group near Salisbury in Wiltshire.

Resplendent in its familiar John Deere green and yellow livery the new 300M sprayers are the latest and, possibly, final step in the ‘Deerification’ of the Mazzotti models that the firm acquired in 2017.

These 3,000-litre and 4,000-litre machines, are not, however, a simple makeover. While the colour scheme undoubtedly adds to the appeal, a quick look at the size and spec show it’s obviously a sprayer aimed squarely at the UK market.

While the sprayer is still based on the Mazzotti and built in Ravenna, Italy, the specification is, although not entirely new, significantly different to existing equivalent models in the range. Also, unlike the Mazzotti, they will be available through the entire John Deere dealer network.

There are two new models:

- The 3,000-litre 332M is powered by a 4-cyl, 175hp engine with booms up to 28m wide. Unladen weight is from 7.5t – 8.1t.

- The 4,000-litre, 340M has a 6-cyl 225hp engine is fitted with booms up to 36m wide. Unladen weight is from 8.5t – 9.5t.

Redesigned chassis

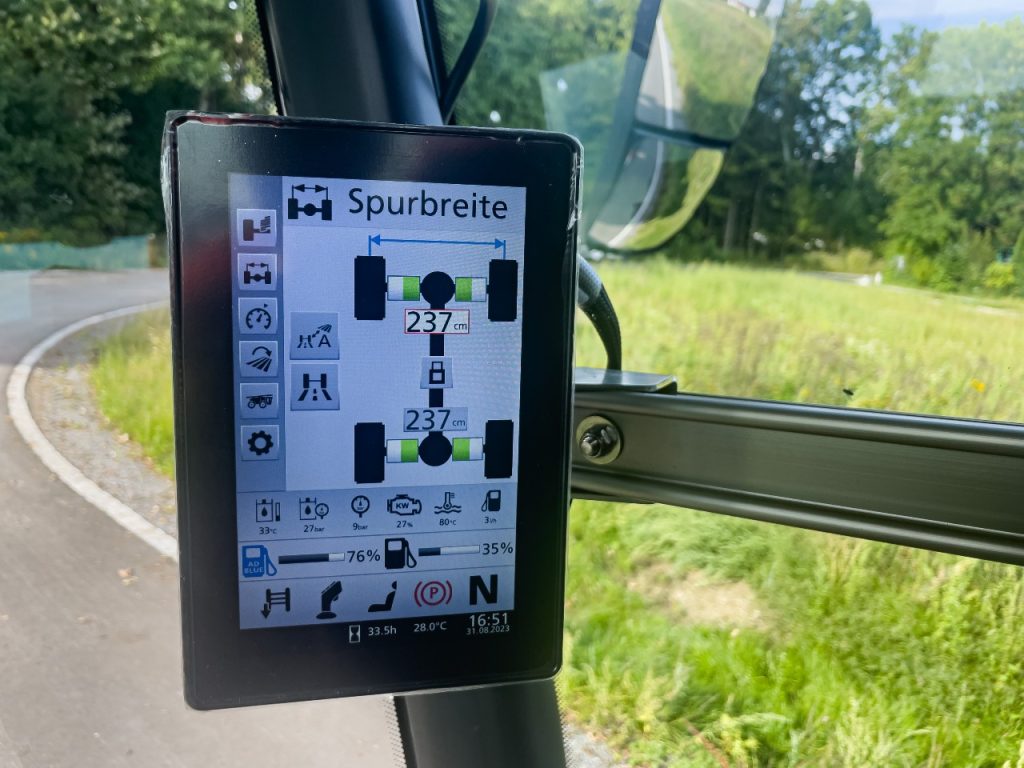

Sitting on a new chassis design both have an updated cab, uprated twin-pump hydrostatic transmission, manual or hydraulic track width adjustment and up to 650/60R38 VF tyres. Standard specification includes individual nozzle control, auto-boom height, PowrSpray, auto-rinse as well as Starfire 7000 receiver, latest G5 terminal and JDLink.

Here we focus on the larger 340M machine, but apart from the power and tank size, both models are similar.

A big change is found on the chassis beam, which is resigned to accommodate mounting the engine 250mm lower than before. This also provides completely clear access to the engine, which is found under a lifting ‘bonnet’.

It also has a 300mm longer wheelbase than the smaller model, to maintain the 50/50 weight distribution. Four-wheel steer offers a quite tight, outside turning radius of 5.1m.

Unlike the Mazzotti, the height is not adjustable – providing a fixed 110cm clearance on standard wheels. There is also now the option to fit up to 650/60/R38 VF tyres or 380/90/46 row crops.

There’s a choice of three, adjustable track widths: 1.5m – 1.8m, 1.8m – 2.25m or 2.25m – 3.0m.

Uprated transmission

While there are significant transmission changes it still employs two Sauer Danfoss hydrostatic pumps. These are now in a split circuit with one supplying the front wheels and the other the rears.

Poclain MHP11 High Performance wheel motors are fitted as standard. As well as providing hydrostatic braking, the front ones also include ‘proper’ disc brakes (a requirement for the 50km/h road speed).

A new management system controls engine rpm and transmission, which also provides a simple speed limit setting – to set a top speed – as well as Ecomode for 50km/h on the road, at 1,750rpm engine speed.

The engine is the well known and proven, six cylinder 6.8 litre, PowerTech, which delivers 225hp in the 340M.

A wide walkway around three sides offers really great access. On the offside, the air filter and hydraulic filters are easy to reach while on the nearside you will find the fuel filters. The AdBlue filler is found under a flap on the floor.

Mid-spec cab

Repositioning the engine also creates a big gap behind the cab, which is said to help reduce noise. It’s the same cab that’s sourced from John Deere Brazilian combines that’s been used before, but with a much improved finish and fit. Cat V filtration is standard and provided by a rather ungainly box on the cab roof.

Star of the cab show, however, is the latest John Deere G5 universal terminal, with a high definition display and more processing power, plus a lifetime subscription to JDLink for automatic wireless transfer to the John Deere Operation Center.

Standard specification also includes a Starfire 7000 GPS receiver (with a choice of RTK, new SF RTK or StarFire 1), individual nozzle control and TerrainCommand Pro auto-boom height. All operated through the G5 display.

John Deere operators will be happy to see the familiar CommandArm joystick, mounted on the right console. Comfortable to use, it provides comprehensive thumb button control of all the main sprayer functions – boom variable geometry, up/down, on/off and sections.

The console layout is now tidier, with stop switch, throttle and steering settings to the right of the joystick and further controls on a sloping front panel.

Inside, the cab’s not enormous, but spacious enough with a slightly wider buddy seat than before. Visibility is excellent, especially to the rear through curved rear windows providing a great view right to the end of a 36m wide boom. The electrically adjustable mirrors also provide a clear view along the whole side of the machine.

Storage seems a bit sparce, with just a slot for a folder behind the buddy seat and cupholder on the right, behind the driver’s seat. Apart from space underneath the buddy seat that’s it. The PPE storage is found by lifting a lid on the walkway beside the cab – its not a great location for something that should be put on/off so often.

Elsewhere the only other locker we could find is on the off-side, next to the battery box. About 1m long and 50cm high it’s got an easy to open lid on struts – but still much less than that found on equivalent machines.

PowrSpray package

One area that remains largely unchanged is the dual circuit, hydraulically driven PowrSpray system, which is the same as that used on the R700i trailed sprayers.

For spraying there is a separate 750 litre/min centrifugal pump. Hydraulic drive means pressure and application are adjusted by controlling the pump speed. John Deere says the system achieves the set target rate 98% of the time, much more accurate when compared to a piston diaphragm pump and pressure regulator.

Control is by the firm’s well-known Solution Command system. This provides a wide range of push-button, automated operations including filling, agitation, spraying and rinsing.

A nice touch is how the induction hopper can be hydraulically raised and lowered to any position – even down to the ground. Handy for when loading from larger containers.

Moving to the back of the machine, the 36m wide steel boom fitted to the 340M model, is from Vicon – which also still uses the Mazzotti as the base for its own self-propelled. On the John Deere 340M it is equipped with individual nozzle control as standard, as well as its TerrainCommand Pro (Norac-based) levelling system – with three or five sensors, depending on width.

https://www.deere.co.uk/en/sprayers/300m-series/

Need NRoSO or BASIS points?

We offer a range of online courses from two to eight points.