Why droplet size matters

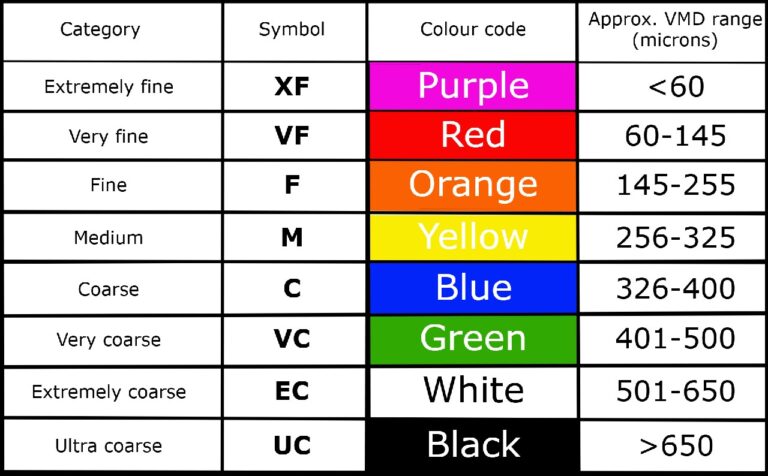

An international standard classifies a nozzle’s droplets in broad terms of fine, medium, coarse and puts a figure on their actual size. But within each classification there’s a wide range of drop sizes.

This range is known as the ‘droplet spectrum’ and there is also a relationship between nozzle size and drop size.

- Larger nozzles will usually produce a spectrum containing a higher number of bigger drops, than smaller sized nozzles

- Smaller nozzles will typically produce more smaller drops.

A key point that applies to all nozzles is:

- The higher the pressure, the finer the spectrum produced

- Conversely, if the pressure reduces, it produces a coarser spectrum.

While drop size has a significant influence on spray behaviour, other physical factors such as energy (pressure), trajectory, shock absorption and patternation also have a big effect on the efficacy of application.

Measuring in microns

The wind tunnel at Silsoe Spray Applications Unit, measures droplet sizes and drift from nozzles on test.

Drop size is usually expressed in microns (μm). 1 micron = 1/1,000mm

(1 micron is about 75 times smaller than a human hair).

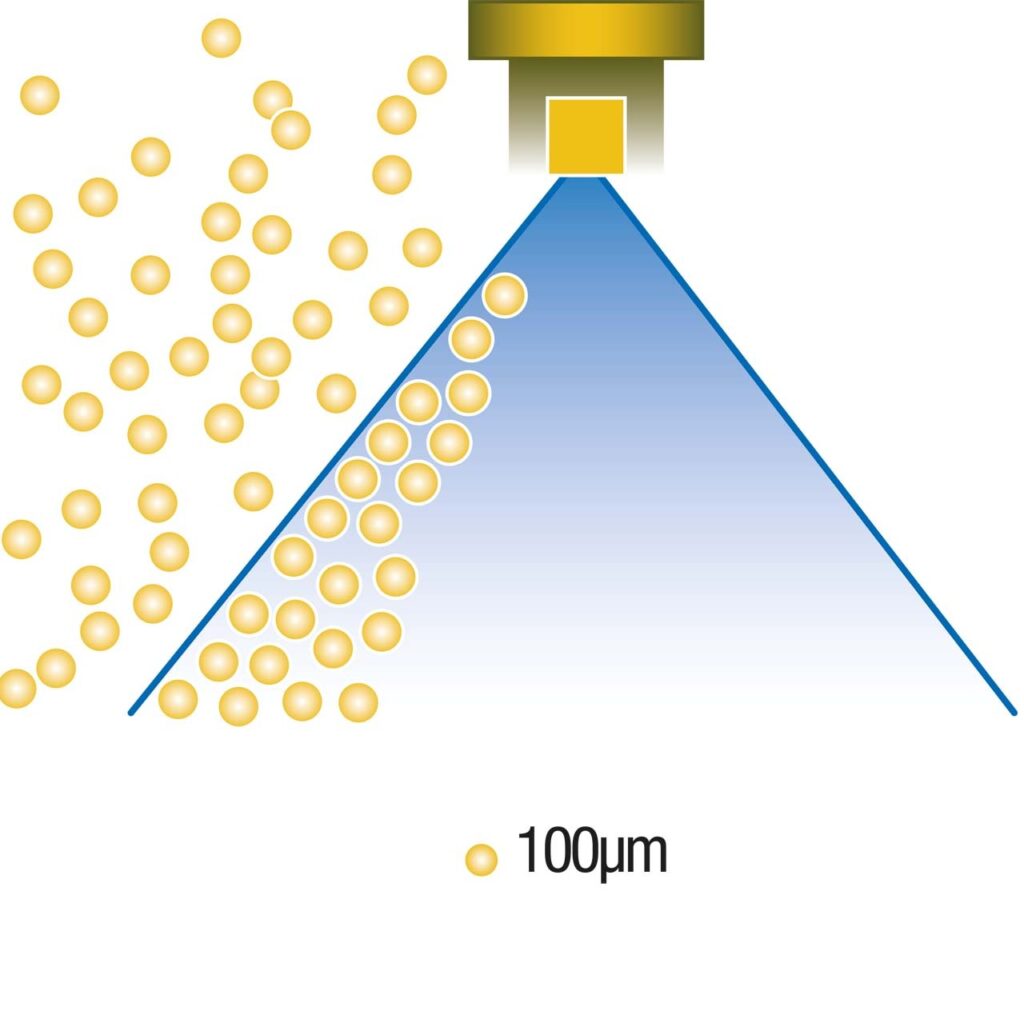

When comparing the drop size between different nozzles the volume of drops less than 100 microns is of particular interest. This is because this is a good indication of the amount of drift that the nozzle and setting will produce.

You can be reasonably certain a spectrum containing 6% (by volume) of drops less than 100 microns (left) (Pic 4) will be twice as drifty as a spectrum containing 3% less than 100 microns (right) (Pic 5).

What is VMD?

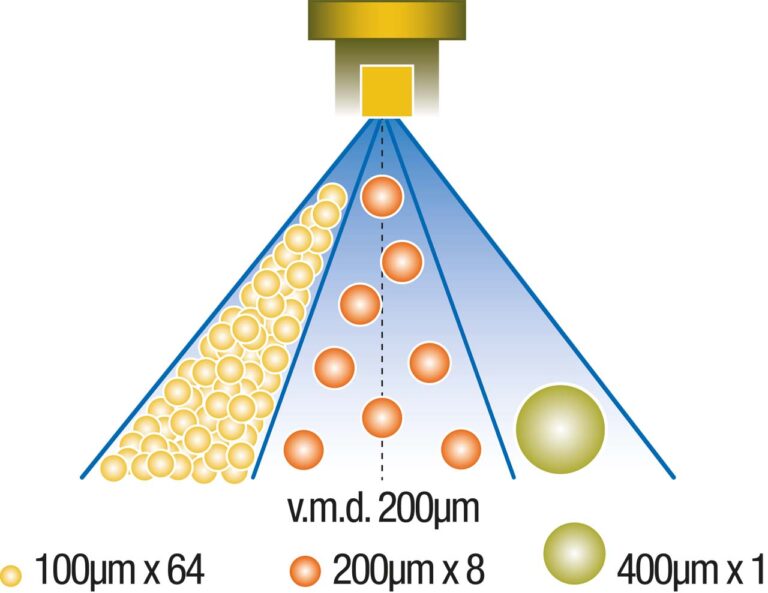

Volume Median Diameter (VMD) refers to the midpoint droplet size (median) – where half of the volume of spray is in droplets smaller than the median, and half of the volume is in droplets larger than the median.

Halving the size of a drop will increase the number of droplets by a factor of eight.

Why is VMD important?

Knowing the VMD is important because it indicates the characteristics of the ‘non-drifty’ part of the spectrum. And this where the fine, medium and coarse classifications come in.

There is, however, a minimum and maximum VMD for each classification band. The differences in the number of drops, and their behaviour between the top and the bottom of the band, will influence the performance of the spray. This effect increases with the coarseness of the spectrum.

Coarser droplets

With increasing emphasis on drift reduction, there is a move to coarser droplets – often produced by air inclusion (AI) nozzles. While this means there will be fewer drops, field trials show that the better control these larger drops provide can create a more effective spray than more smaller drops with less control.

Flat fan nozzles on the right hand side are clearly creating drift compared with the GuardianAirs on the left hand side.

Drop size maths

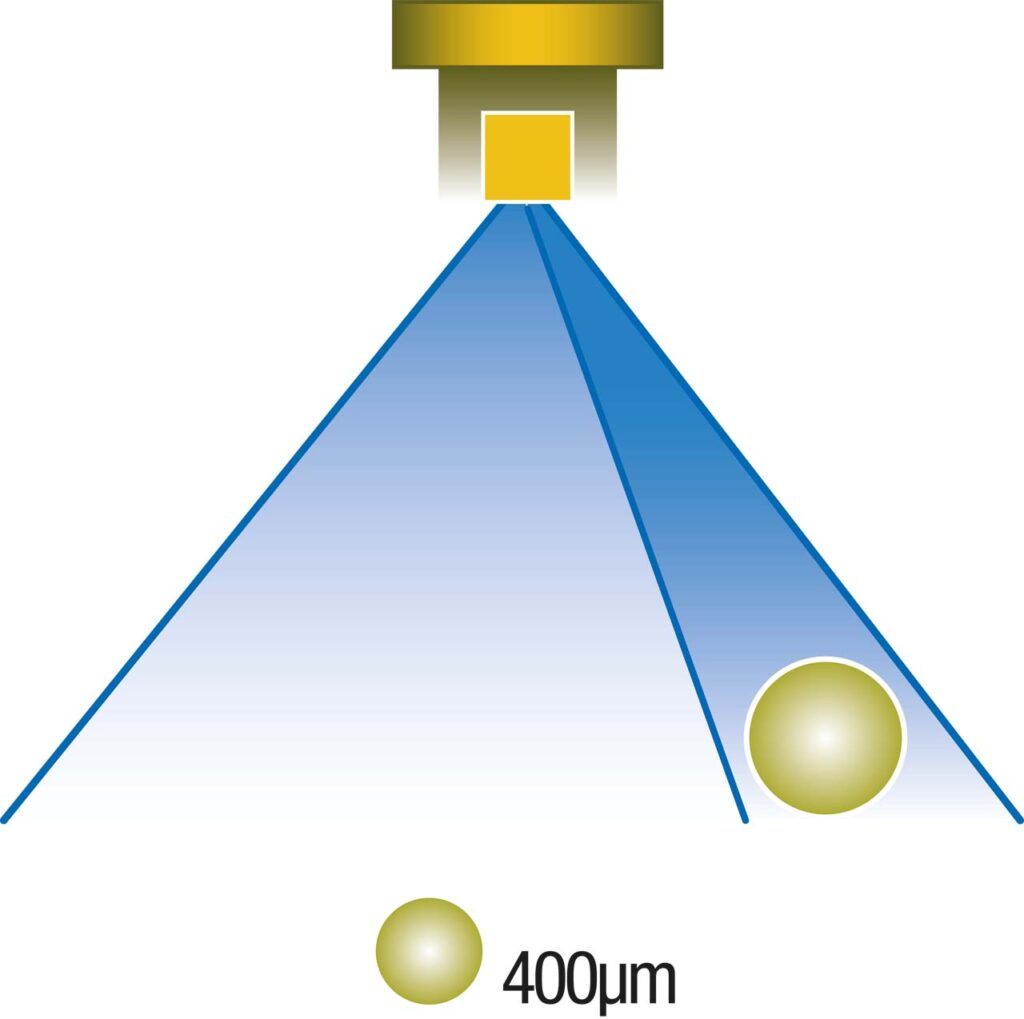

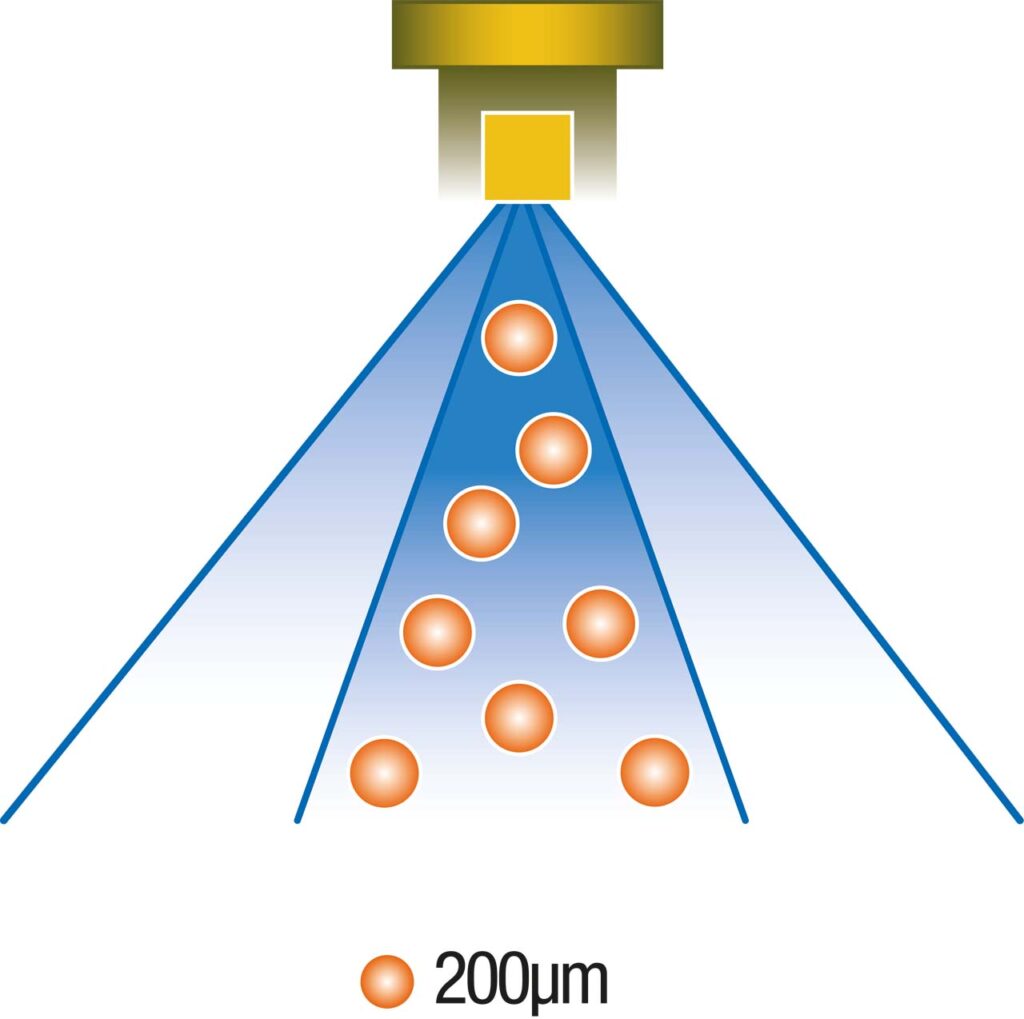

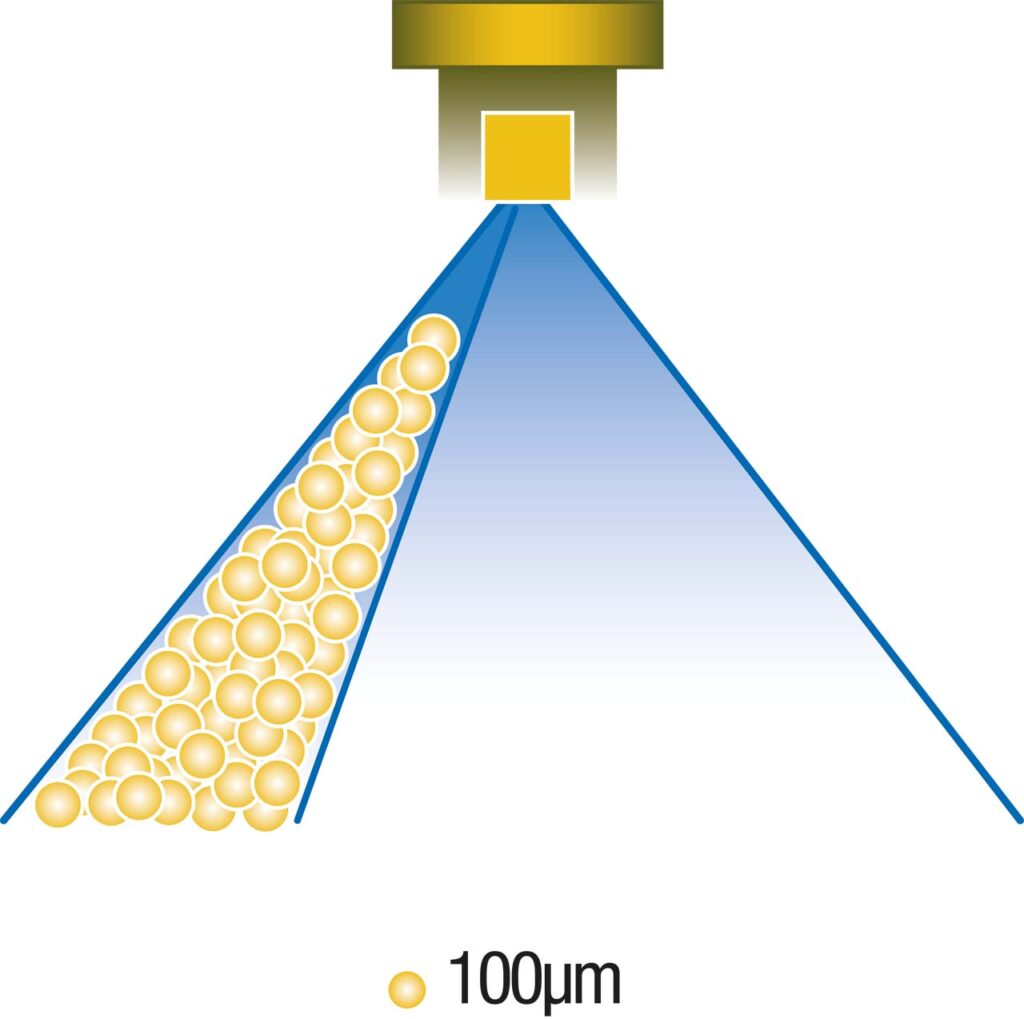

When the diameter of a drop is doubled, its volume increases by a factor of eight: 2x2x2 = 8.

When the drop size is halved the number of drops for a unit volume of liquid increases eight-fold.

1 x 400 micron drop has the same volume as 8 x 200 micron drops and 64 x 100 micron drops.

Why spray physics matter

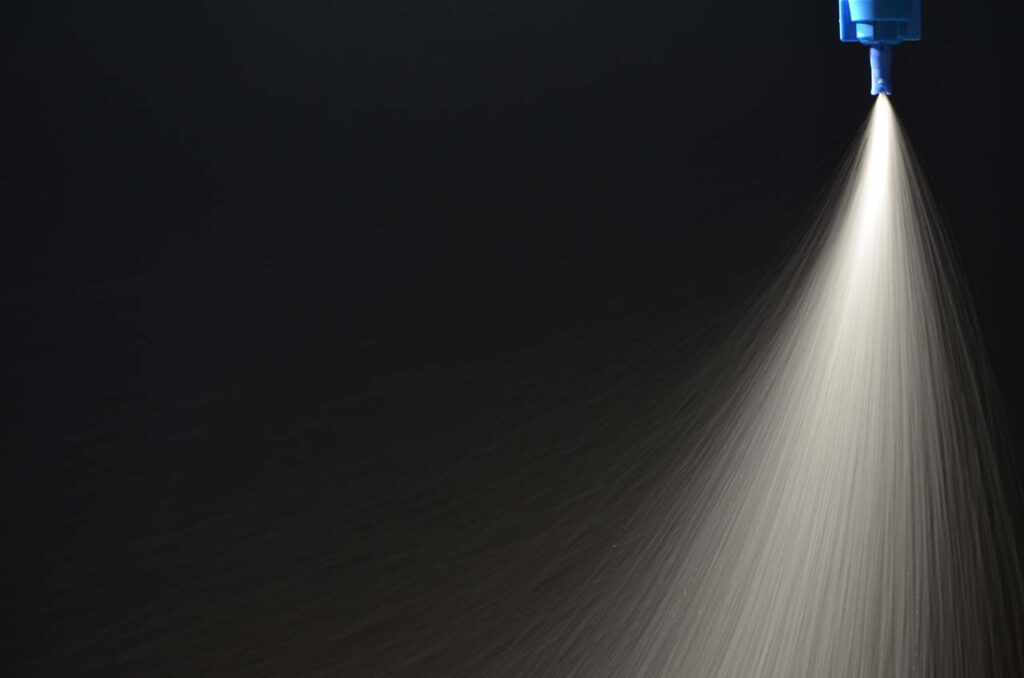

All drops start slowing down and losing momentum from the moment they leave the nozzle.

Traditional flat fan: The spray sheet exits at about 80km/h, and breaks up into random sized drops that can be made coarser by:

- Increasing nozzle size

- Decreasing fan angle

- Reducing pressure

Air inclusion nozzles: The spray sheet exits at about 40km/h and breaks up into random sized drops containing up to 25% air, which can also act as a shock absorber.

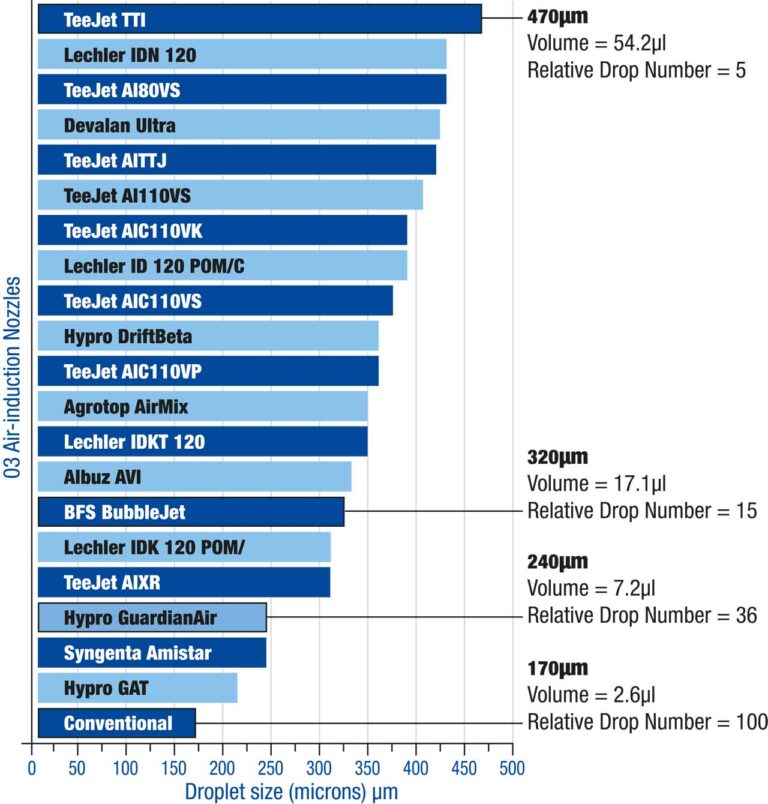

It is important to note, however, for the same sized, but different make of AI nozzle the volume of VMD drops may vary from 240 up to 470 microns. That is from about 2.8 to 20 times the volume compared with a fan jet (170 microns).

A useful guide is the ‘Relative Drop Number’ (RDN), which is used to compare the drop numbers/unit volume of the spray applied by different AI nozzles compared with a traditional flat fan, which has an RDN of 100.

This is just a guide, because AI drop sizes can vary between 2.8 to 20 times that of a flat fan. The AHDB nozzle chart (below) shows actual measured size, volume and number of droplets produced by different AI nozzles.

The AHDB chart clearly shows the huge variance in drop sizes from different 03 AI nozzles. These range from the largest – TeeJet TTI producing a RDN of just five, 470 micron-sized drops with a volume of 54.2 microns, to the Hypro GuardianAir (Syngenta Amistar) that produces 36, 240 micron drops with a volume of 7.2 microns. These are both compared with the flat fan that creates 100, 170 micron drops with a volume of 2.6 microns.

You can download the full AHDB nozzle chart from HERE:

In the next issue of Pro Operator insights, we look at the five key aspects to achieve an effective spray application. In the meantime, why not purchase the two-point Droplet Course and earn NRoSO/BASIS points.